The winding machine is a cornerstone technology in manufacturing, essential for creating precision coils, wires, and other materials wound into specific patterns. From aerospace to medical devices, these machines have undergone remarkable advancements, allowing industries to achieve higher levels of accuracy, efficiency, and customization. One notable player in this field is Guangri Electronic Machinery Company, a renowned Chinese manufacturer specializing in precision winding machines tailored to a variety of industries, including aerospace, medical technology, and energy storage.

This blog explores the evolution of winding machines, their applications across diverse sectors, and how companies like Guangri Electronic Machinery Company are driving innovation in this critical domain.

The Evolution of Winding Machine Technology

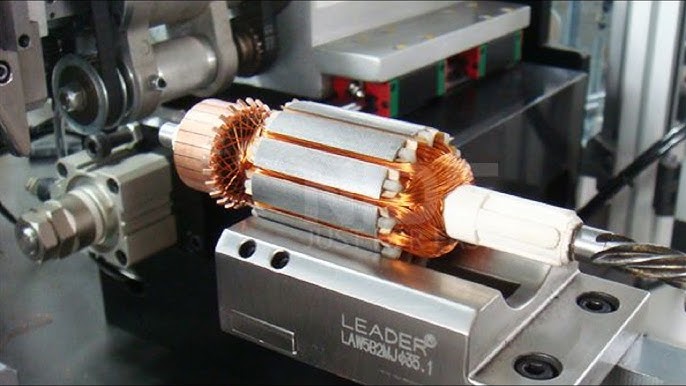

Historically, winding machines were simple manual devices used to wind materials such as yarn, thread, or wire. These early versions required significant operator intervention and had limited precision. As industries expanded and the demand for high-performance products grew, the technology evolved to include automated and programmable features.

In the mid-20th century, the development of electrical and electronic components propelled the need for advanced winding solutions. With the rise of industries like aerospace and telecommunications, manufacturers needed machines capable of winding ultra-thin wires with pinpoint accuracy. Today, modern winding machines integrate cutting-edge technologies such as AI, machine learning, and IoT to deliver unparalleled precision and efficiency.

One company leading the charge in this technological transformation is Guangri Electronic Machinery Company, known for its innovative approach to designing winding machines. By incorporating advanced control systems and high-speed capabilities, Guangri has set a new standard in the industry, making their machines indispensable in high-tech manufacturing environments.

Industry-Specific Applications of Winding Machines

Aerospace Industry

The aerospace sector demands precision and reliability, particularly in the production of components like electromagnetic coils and transformers. Guangri Electronic Machinery Company has developed specialized winding machines designed to meet these exacting standards. These machines ensure consistent wire tension and precise layering, which are critical for creating components that can withstand extreme conditions.

By using advanced winding techniques, such as tension-controlled winding and distributed winding patterns, aerospace manufacturers can produce lighter, more efficient components. Guangri’s machines are particularly valued for their ability to handle ultra-thin wires used in high-frequency applications, enabling the production of cutting-edge avionics and communication systems.

Medical Technology

In the medical field, precision is not just desirable—it is a necessity. Winding machines play a crucial role in manufacturing devices such as MRI coils, pacemakers, and other diagnostic equipment. Guangri Electronic Machinery Company has tailored its offerings to address the stringent quality requirements of this industry.

Modern medical devices often involve complex coil geometries that require highly specialized winding processes. Guangri’s machines are equipped with advanced control systems that allow for the production of intricate designs with minimal error margins. This precision ensures the reliability and effectiveness of life-saving medical technologies.

Energy Storage and Renewable Energy

The shift toward renewable energy and sustainable practices has increased the demand for efficient energy storage solutions. Winding machines are instrumental in producing components such as battery packs, transformers, and inductors used in solar panels and wind turbines. Guangri Electronic Machinery Company has developed machines specifically for these applications, focusing on scalability and efficiency.

One notable innovation is Guangri’s capability to handle large-scale winding projects, such as those required for electric vehicle batteries and energy storage systems. Their machines can process high-performance materials while maintaining consistent tension and alignment, crucial for the longevity and efficiency of energy storage devices.

Advanced Winding Techniques Driving Innovation

The continued evolution of winding machines has been fueled by the development of advanced winding techniques. These methods not only improve the quality of the end product but also enhance production efficiency. Here are some notable techniques that have transformed the field:

- Multi-Axis Winding: This technique allows for the creation of complex three-dimensional coil shapes, essential in industries like aerospace and medical devices. Guangri’s machines are at the forefront of multi-axis winding technology, enabling manufacturers to push the boundaries of design.

- Tension Control: Maintaining consistent tension during the winding process is critical for preventing defects. Modern winding machines, such as those produced by Guangri, feature real-time tension monitoring and adjustment systems, ensuring superior product quality.

- Distributed Winding: This approach involves evenly distributing the winding material across the core to minimize losses and improve efficiency. It is particularly beneficial in applications like transformers and inductors, where performance optimization is key.

- Smart Winding: By integrating IoT and AI, manufacturers can monitor and control the winding process remotely, reducing downtime and enhancing productivity. Guangri’s latest machines incorporate these technologies, making them highly versatile and future-ready.

Guangri Electronic Machinery Company: A Leader in Precision Winding Solutions

Headquartered in China, Guangri Electronic Machinery Company has established itself as a leader in the design and manufacture of winding machines. Their commitment to innovation and quality has earned them a reputation as a trusted partner for industries worldwide.

Guangri’s success can be attributed to several factors:

- Customization: The company offers tailored solutions to meet the specific needs of each industry, whether it’s aerospace, medical, or energy storage.

- Technology Integration: Guangri consistently integrates the latest technologies into its machines, ensuring they remain at the cutting edge of the field.

- Global Reach: With a strong presence in international markets, Guangri has demonstrated its ability to deliver world-class products and support.

Their focus on customer satisfaction and continuous improvement has made them a go-to choice for precision winding solutions.

The Future of Winding Machines

As industries continue to evolve, the role of winding machines is set to become even more critical. Emerging trends such as miniaturization, energy efficiency, and smart manufacturing will drive the demand for more advanced and versatile machines. Guangri Electronic Machinery Company is well-positioned to lead this charge, with a proven track record of innovation and excellence.

In the coming years, we can expect to see further integration of AI, robotics, and IoT in winding machines, enabling even greater precision and productivity. As the world moves toward more sustainable and high-tech solutions, companies like Guangri will play a pivotal role in shaping the future of manufacturing.

Conclusion

The winding machine has come a long way from its humble beginnings, evolving into a sophisticated tool that underpins some of the most critical industries today. With applications spanning aerospace, medical technology, and energy storage, these machines are indispensable in modern manufacturing.

Guangri Electronic Machinery Company stands out as a leader in this field, offering cutting-edge solutions that meet the diverse needs of its customers. By embracing innovation and focusing on quality, Guangri continues to set new benchmarks in the industry.

As technology advances, the importance of winding machines will only grow, making them a vital component of the industrial landscape. Whether it’s creating components for space exploration, life-saving medical devices, or renewable energy systems, winding machines and their manufacturers will remain at the heart of progress.